emerging technology

What We Do

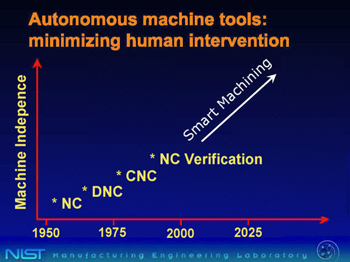

VeritasCNC Inc. is a technology innovator, developing Smart Machining products to optimize CNC operations. Our patented strategies integrate cutting edge software with on-line CNC data to make parts cheaper, faster, better.

Keep It Simple

VeritasCNC converts the tool information into plain, machinist-friendly gauges and

charts. You don’t need to be an auto mechanic to drive your

car. You don’t need a PhD to use our tool wear gauge.

The Magic that Drives the Technology

The VeritasCNC Smart Machining products are the first applications to

implement a practical integration of NC verification software with

CNC hardware data.

NC Verification

NC verification was pioneered by the principals behind VeritasCNC. At

the 2002 NIST Conference on Smart Machining, NC verification was presented

as the most significant advance since the introduction of CNC in the

progress towards autonomous manufacturing. The VeritasCNC Smart Machining

system will set a similar standard for 21st Century Manufacturing.

Tool Wear

Ever break a tool? Score a part? Lose tolerance due to a worn tool? Unexpected

tool wear can disrupt production and damage parts. Most of the time,

you take care to replace tooling. But tool wear is not very predicable

and surprises happen.

Tool Wear Gauge

VeritasCNC offers a reliable tool wear “gauge” that

will inform you of the tool’s condition from the very first part.

No costly and difficult tool condition monitor training period. The gauge

will even tell you what type of wear is happening. Progressive (“flank”)

wear is the most common type of wear. But sometimes other types of wear

can occur (“notch wear”, “crater wear”, …)

that are localized on your tool and can progress rapidly after on-set.

Our gauge will alert you to rapidly changing and potentially damaging

tool wear.

How Do We Do It?

Anyone who has tried to make a hole with a worn-out drill bit knows that

wear means increased forces. The relation between tool wear and tool

forces has been an academic topic for decades. Research labs have measured

tool forces with expensive and complex force sensors. VeritasCNC, in

collaboration with our research partners, has developed a simple, transparent

strategy for measuring tool forces.

Tool forces are complex and rapidly changing at the cutting tip. We have demonstrated that we can measure high-bandwidth tool forces by an intelligent combination of easily-accessible spindle power data and an integrated geometric & physics-based model of the cutting process. If your control has an “open architecture” interface, we can obtain the spindle power directly from the control with no additional hardware. If you have a legacy control, we can measure power with an inexpensive and unobtrusive power meter such as the Load Controls Inc. (Sturbridge, MA) sensor shown here.

The spindle power and our intelligent models team up to provide tool forces. We analyze your tool forces, using patented and patent pending methods, to monitor, predict and diagnose your tool wear.